The packaging industry is undergoing a rapid transformation as businesses increasingly invest in technologies that help them optimize their packaging processes while reducing costs and improving efficiency. One such technology that is gaining momentum in the packaging industry is robotic packaging systems.

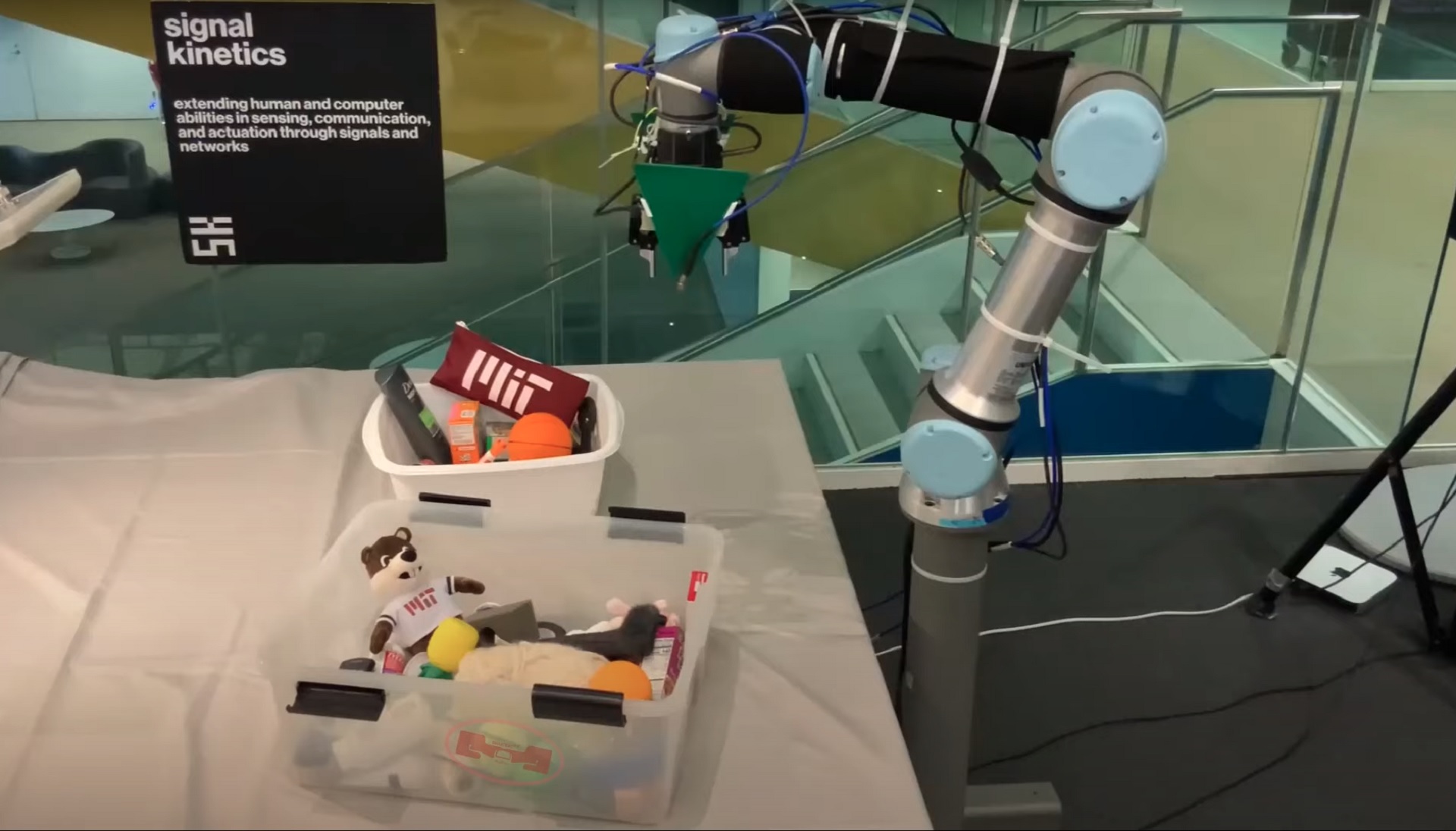

A robotic packaging system is an innovative solution that optimizes the packaging process by performing various tasks such as picking, packing, labeling, and palletizing products. Robotic packaging systems utilize advanced technologies such as artificial intelligence, machine vision, and deep learning algorithms to process data and make informed decisions.

One of the main advantages of robotic packaging systems is their flexibility. These systems can be designed to handle a wide range of products, from small electronic components to large machinery. They can be easily configured to perform different packaging tasks without the need for expensive reconfiguration or modifications to the production line.

Moreover, robotic packaging systems are highly accurate and reliable. They can perform repetitive tasks with precision and consistency, reducing the risk of errors and increasing the overall quality of the packaged products. This translates to lower maintenance costs, reduced waste, and greater customer satisfaction.

Nowadays, businesses are increasingly turning to robotic packaging systems due to their cost-effectiveness. Automation helps to minimize labor costs, increase productivity rates, and reduce material costs, resulting in a significant return on investment (ROI). Additionally, the automation of packaging processes helps businesses to meet their sustainability goals by minimizing waste and reducing their carbon footprint.

Finally, robotic packaging systems are user-friendly and require minimal human intervention. They can be easily programmed and monitored through user-friendly interfaces, reducing the need for highly skilled workers to operate them. As a result, businesses can reduce their training costs and increase their operational efficiency.

In conclusion, robotic packaging systems are the future of the packaging industry. They offer a wide range of benefits, including reduced labor costs, increased productivity, improved quality, and increased sustainability. Businesses should embrace this technology to optimize their packaging processes and remain competitive in an increasingly automated world.