The packaging industry is constantly evolving, seeking new and innovative ways to boost efficiency and productivity while reducing costs. One of the ways in which this is being achieved is by adopting robotic palletizers, which have revolutionized the way products are packaged and shipped.

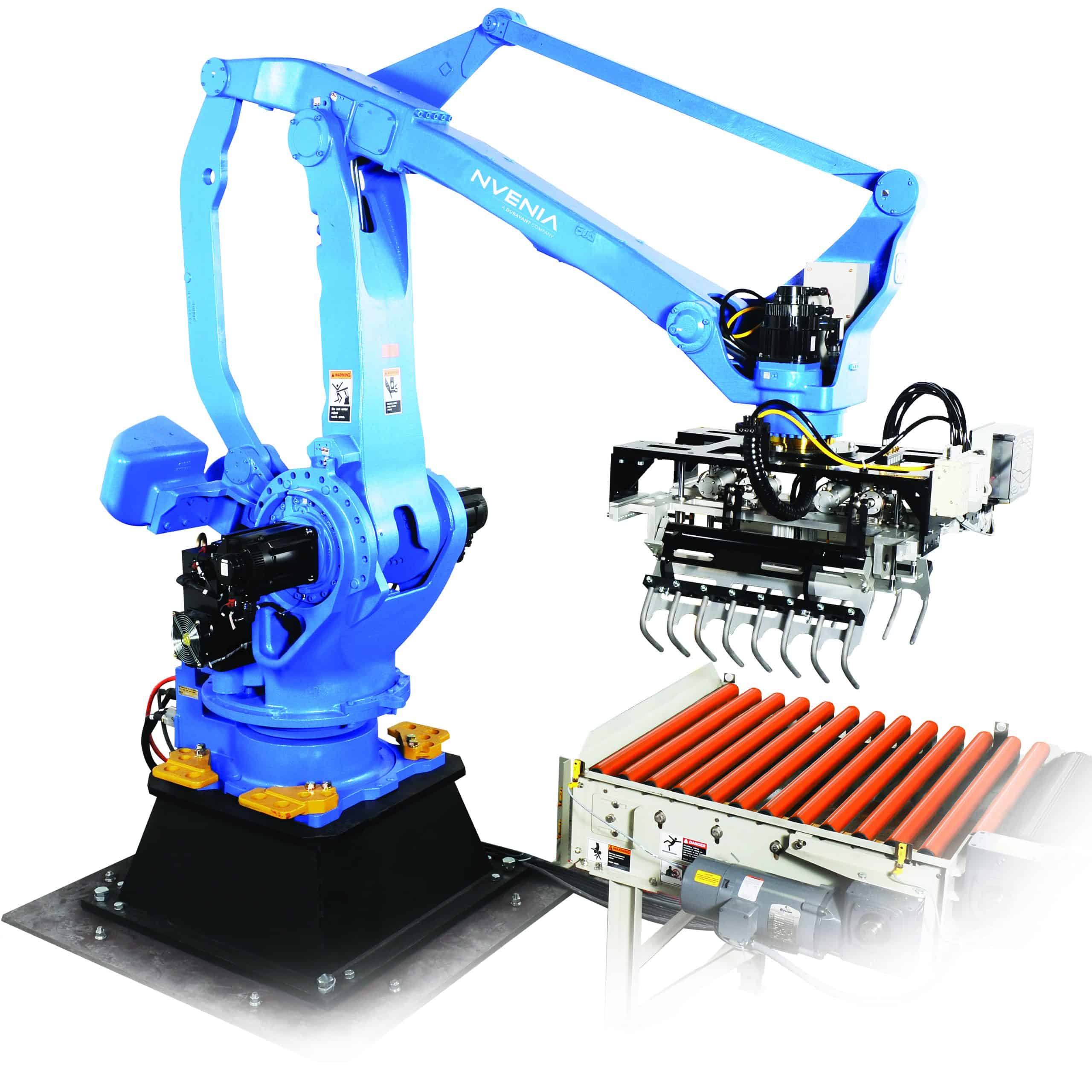

Robotic palletizers are machines that automatically load products onto pallets, replacing manual labor and increasing efficiency. These robots can work 24/7, which ensures production never stops, thereby increasing output and minimizing downtime. Additionally, they are able to move heavy packages with ease, saving workers from injuries and strain.

Despite the cost of investment being higher than traditional manual labor, robotic palletizers are a worthwhile investment in the long run. The return on investment (ROI) is high, as these robots can handle an increased workload, which means more products can be packaged and shipped. Not only do they increase productivity, but they are also cost-effective, reducing labor costs over time. This is because manual labor requires more time and effort, thus requiring more workers to perform the same task.

In recent years, technology has made it possible for robotic palletizers to be smarter, quicker, and more reliable than their predecessors. This means that modern palletizers can be programmed to perform a range of tasks, including stacking, sorting, and shipping packages in different sizes and shapes.

A distributor, like Shanghai Jiesheng robot, can provide necessary maintenance and service in addition to the purchase. Regular maintenance helps keep the robot in good working condition, preventing downtime due to a failure or breakdown.

Additionally, current pandemic restrictions and lockdowns have resulted in labor shortages, making it difficult for businesses to fulfill orders on time. This is another reason why robotic palletizers come in handy during these challenging times. The automation of the packaging process reduces the dependency on a human workforce and stabilizes production even when there is a shortage of human labor.

Overall, robotic palletizers offer companies in the packaging industry a range of benefits, from increased productivity to cost savings and a reduction in labor dependency. As robotic technology continues to evolve, it is expected that these machines will become even smarter and more efficient, offering even more value to businesses. Therefore, businesses that are looking to streamline their operations in the packaging industry should consider the implementation of robotic palletizers as part of their strategy to stay ahead of the competition.